Investing in a crusher plant is a significant undertaking for any business involved in industries like construction, mining, or recycling. While the benefits of having a crusher plant are substantial, the initial investment cost can be daunting.

Thorough Feasibility Study

Before diving into any crusher plant project, conducting a comprehensive feasibility study for the stone crusher plants is essential. This study should assess the potential benefits, risks, and financial implications of the investment. It should include:

Market analysis: Understanding the demand for crushed materials in your target area.

Cost analysis: Estimating the initial investment cost, operational expenses, and potential revenue.

Risk assessment: Identifying potential challenges and risks that could impact the project.

Regulatory compliance: Ensuring that the project complies with all local, state, and federal regulations.

A well-prepared feasibility study can help you make informed decisions and avoid costly mistakes during the project.

Optimize Equipment Selection

Choosing the right equipment is crucial for reducing investment costs. Consider the following factors when selecting crushers and associated machinery:

Capacity: Ensure that the equipment matches your production requirements without being overcapacity, which can be more expensive.

Used vs. New: Evaluate whether used or refurbished equipment is a viable and cost-effective option.

Efficiency: Invest in crushers and screens that offer high efficiency and productivity to maximize output.

Maintenance: Select equipment with a reputation for reliability and easy maintenance, which can save on long-term operational costs.

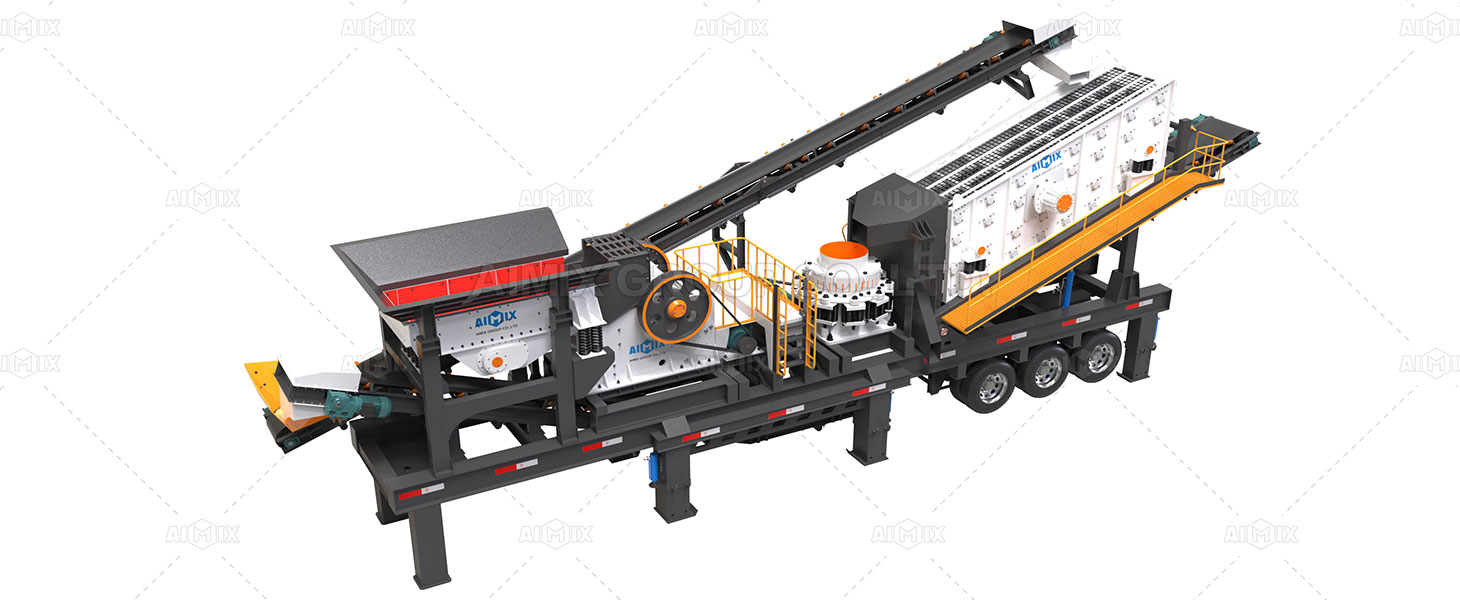

Consider Mobile Crushers

Mobile crushers offer distinct advantages when it comes to reducing initial investment costs. They are mounted on wheels or tracks, providing mobility and flexibility. Here’s why mobile crushers are a cost-effective choice:

Reduced infrastructure: Mobile crusher plants often require less infrastructure, such as foundations and conveyors, compared to stationary plants.

Easy relocation: Mobile crushers can be relocated to different sites, reducing the need for multiple fixed installations.

Lower transportation costs: Mobile crushers can be transported to the material source, reducing transportation expenses.

Scalability: Mobile crushers can be scaled up or down to match the specific needs of your project.

Explore Financing Options

Exploring various financing options can help spread the initial investment cost over time, making it more manageable. Consider options like equipment leasing, equipment financing, or seeking financial incentives and grants from government programs or industry associations. These strategies can help reduce the immediate financial burden of purchasing and installing a crusher plant.

Efficient Site Planning and Layout

Efficient site planning and layout can significantly impact your investment costs. Properly designed layouts can help you minimize the need for extensive site preparation and infrastructure. Key considerations include:

Location: Choose a site that is geographically advantageous and minimizes transportation costs for raw materials and finished products.

Conveyor Systems: Optimize conveyor routes to minimize material handling distances, reducing operational costs.

Safety and Regulations: Ensure that the site layout complies with safety regulations and environmental requirements, preventing costly redesigns and retrofits.

Energy Efficiency

Energy costs can be a significant portion of the operational expenses for a stationary crushing plant. Investing in energy-efficient equipment and implementing energy-saving practices can lead to substantial long-term savings. Consider:

Energy-efficient crushers: Choose crushers that are designed for maximum energy efficiency, such as those with variable speed drives.

Regular maintenance: Keep equipment well-maintained to ensure optimal energy performance.

Renewable energy sources: Explore the possibility of using renewable energy sources, such as solar or wind, to power your crusher plant.

Training and Knowledge

Investing in employee training and knowledge can reduce long-term operational costs and increase the overall efficiency of your crusher plant. Well-trained operators can maximize the productivity of the equipment, reduce downtime, and extend the lifespan of the machinery. Training programs can also focus on safety practices, preventing accidents and costly downtime. View more tips on: https://aimixgroup.id/.

Conclusion

Investing in a crusher plant is a significant step for any business, but with careful planning and strategic considerations, you can reduce the initial investment cost while optimizing the long-term benefits. Conducting a thorough feasibility study, selecting the right equipment, exploring financing options, efficient site planning, energy efficiency, and investing in training are all key strategies to lower your investment costs. By taking these steps, you can make the crusher plant project more financially viable and position your business for long-term success in your industry.